Only a few of the many applications:

All shown applications are executed by MBR

ELECTRONIC GmbH ultrasonic soldering systems.

Pictures: all rights reserved by MBR ELECTRONIC GmbH Switzerland.

|

Germanium Monocrystal Pretinning the edges for contacting purposes. |

|

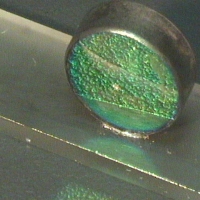

Special Optics Soldering a stainless steel sleeve onto a special shaped rod-lens. Lens diameter 1,8mm, solderfiller gap 0,1mm |

|

Laser Test set-up A small lens (diameter 3mm) has to be fixed (soldered) onto an AIO plate. The lens is coated at the circumference with NiCr. |

|

Copper on Graphite Two copper wire, diameter 1mm, to be soldered into slots carved in a grahite plate of 1mm thickness. Used special high temp solder alloy |

|

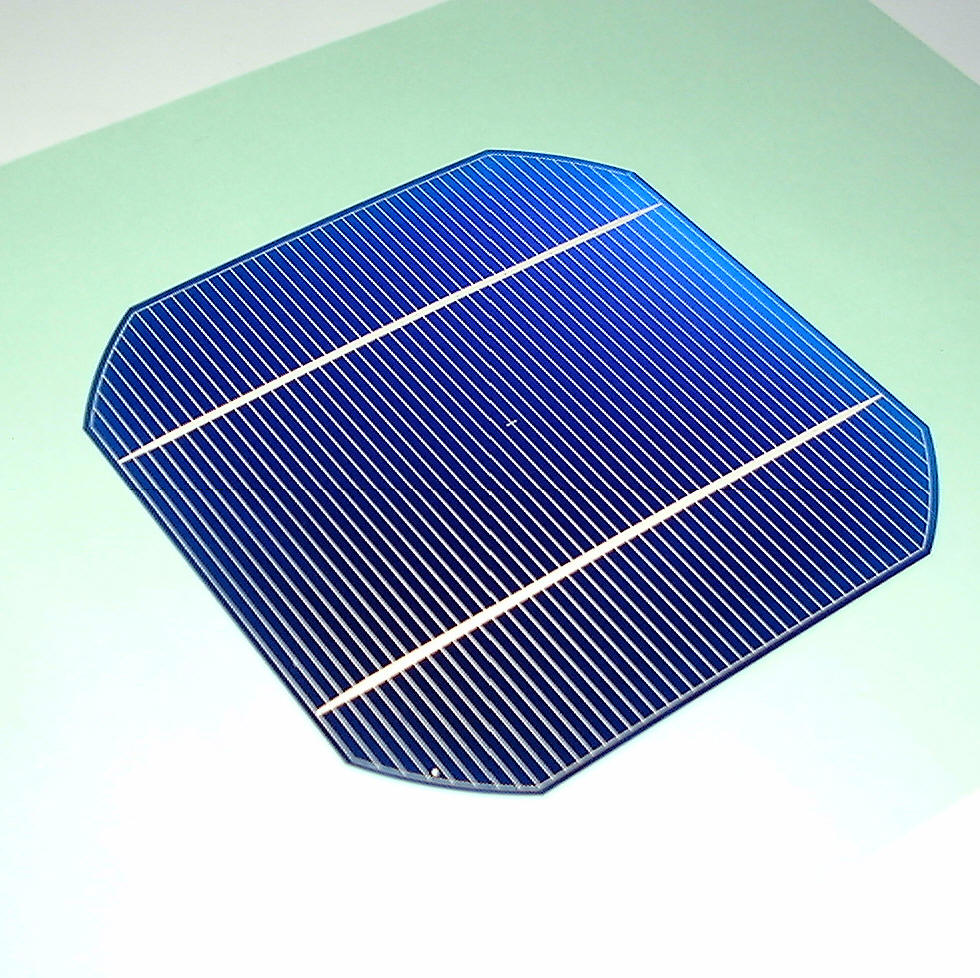

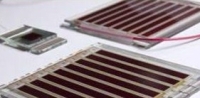

Contacting of solar cells: Si-Wafer, thin-film-cells, Dye-sensitisised cells |

|

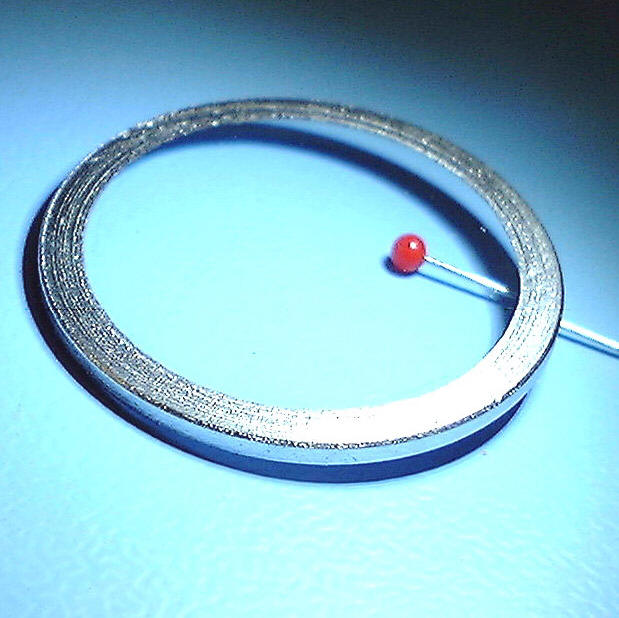

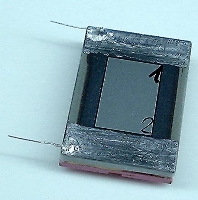

Contacting of Niob coil to a Zerodur rod |

|

Tin-coating/metalizing of optical glasses as preparation for a gas tight soldering into a stainless steel support. |

|

Sensorhead A Be-foil of 25 µm thickness must be soldered onto a stainless steel cup window, hermetically tight. |

|

Sensor Ultrasonic soldering/contacting a sprayed titanium structure on a ceramic plate. |

|

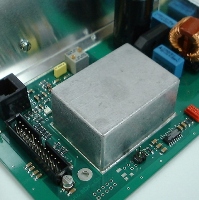

Soldering of an aluminium box

directly onto the PCB to protect/shield of high frequency radiation. |

|

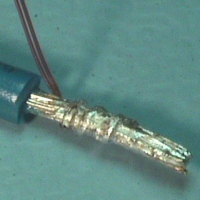

Semi-Rigid Coax SMA coax connector (m/f) with Niobium Titanium NbTi coax cable 0,9mm and 1.6mm diameter. |

|

Microwave Ferrite Producing a metallized area for contacting. |

|

Hermetical Sealing Hermetically sealed mechanical joining of gold plated component on a sapphire tube with the USS-9210 ultrasonic soldering system. |

|

Aluminium Carbon Fibre Partial coating of the aluminium carbon fibre surface with solder alloy. |

|

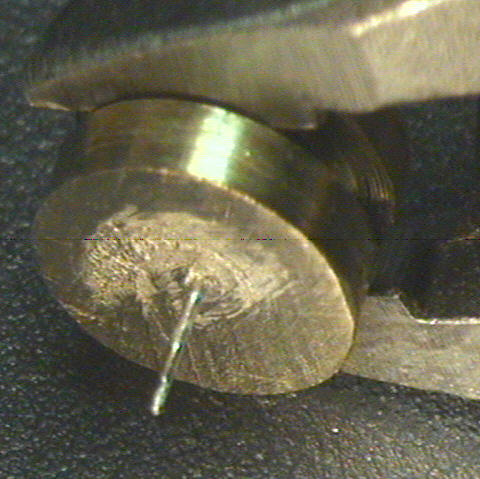

Ceramic Bearing Ceramic-Shere diameter 4mm soldered ultrasonically into a stainless steel socket. Half of shere is out of the socket. |

|

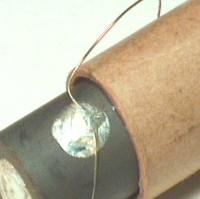

Glass-Fibre Vakuum-tight soldering of glass fibre 120 µm into bronce head with bore of 0.5 mm |

|

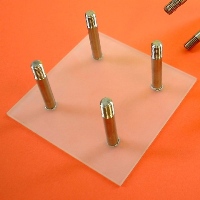

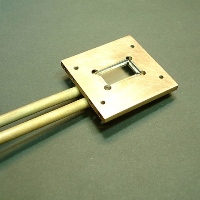

Titanium to Sapphire Mechanical joining of titanium rods on sapphire plate with ultrasonic soldering system USS-9210. |

|

Endoscopic Catheter Flexible catheter, made of stainless steel 304, must be soldered fluxfree to Nitinol NiTi (Nickel/Titanium) alloy. |

|

Cooler Element Copper tube diameter 5mm soldered into a carve of an aluminium plate for optimal heat transfer. |

|

Aluminium Wire Joining an aluminium wire (small) to a copper litzwire (big) by fluxfree ultrasonic soldering. |

|

Si-Wafer to Steel A small Si-Wafer (diameter 20mm) is soldered in full area onto a steelplate. |

|

Sputter Target Sputter target is bonded to a water cooled backing plate. Backing plate is made from copper. The target materials such as W, Ti, Cr, Al, Si, InSnO (ITO), Ce, Ga, Au Pd, Ag etc, need to be bonded to metallic backing plate. |

|

Vaccum Window A round quartzglass, diameter 30mm, soldered into a chrome-coated steel housing. |

|

Saphire Glass Soldering a rectangular window into a water cooled assembly. |

|

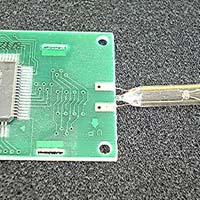

Welding Helmet Auto darkening LCD window. Contacting the LCD-glass soldered ultrasonically to the controller electronics. |

|

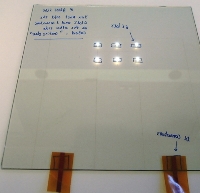

Dye-sensitized Cells With our USS-9210 Ultrasonic Soldering System, contacts can be made onto the glass of organic Perovskite solar cells. |

|

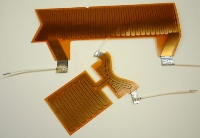

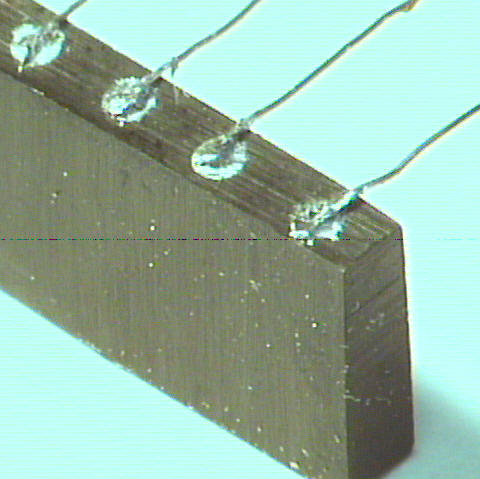

Flex-Heater NiCr Wires soldered onto the NiCr contact lands with our ultrasonic soldering system USS-9210. |

|

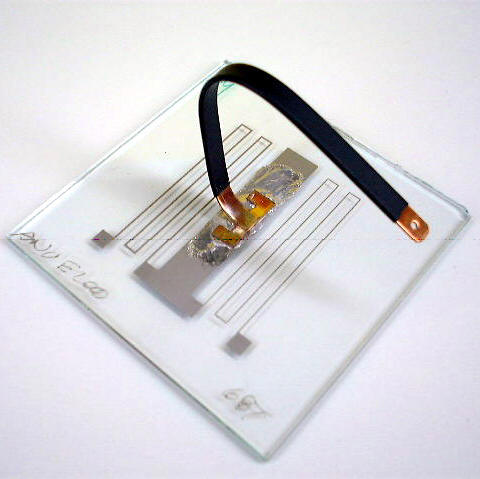

Thin-FIlm ITO on Glass Soldering with the USS-9210 Ultrasonic Soldering System SMT LED onto a transparent window. ITO coating is structured with tracks, like a PCB. |

|

LCD Creating conductive areas with flux-free ultrasonic soldering on the glass test samples. |

|

Titanium Cast Copper wire diameter 0.5mm soldered fluxless with our ultrasonic soldering system USS-9210 to a titanium cast part. |

|

Copper to Aluminum Electrical coating of copper wire on a aluminum track on glass-substrate. |

|

Ceramic Carbon Hybrid Contacts on a ceramic carbon hybrid superconductor. Diameter of the soldering points: 0.8 mm |

|

Applying of the metallisation

Ø 20mm with

solder in the centre

of the aluminum-oxide plate.

Producing at the

same time a

solder

terminal/pad outside the piezodisk dimension. Joining and soldering the piezodisk onto the aluminum oxide plate by heating the parts up to the melting point of the solder alloy. Soldering of the connecting wire. |

|

Stainless Steel Joining / soldering of stainless steel parts. Alternative technology to brazing or welding if components may not be heated over 300°C. |

|

Sensor Fixing of electrical connections on aluminum coating. |

|

Wetting of Aluminm Soldering of power semiconductors on a cooling element (aluminum, aluminum oxide, ceramic etc) to provide best possible thermical connection. |

|

Direct fluxfree tinning/soldering of tungsten (wolfram) wires. |